填写详细信息 律师马上回复。

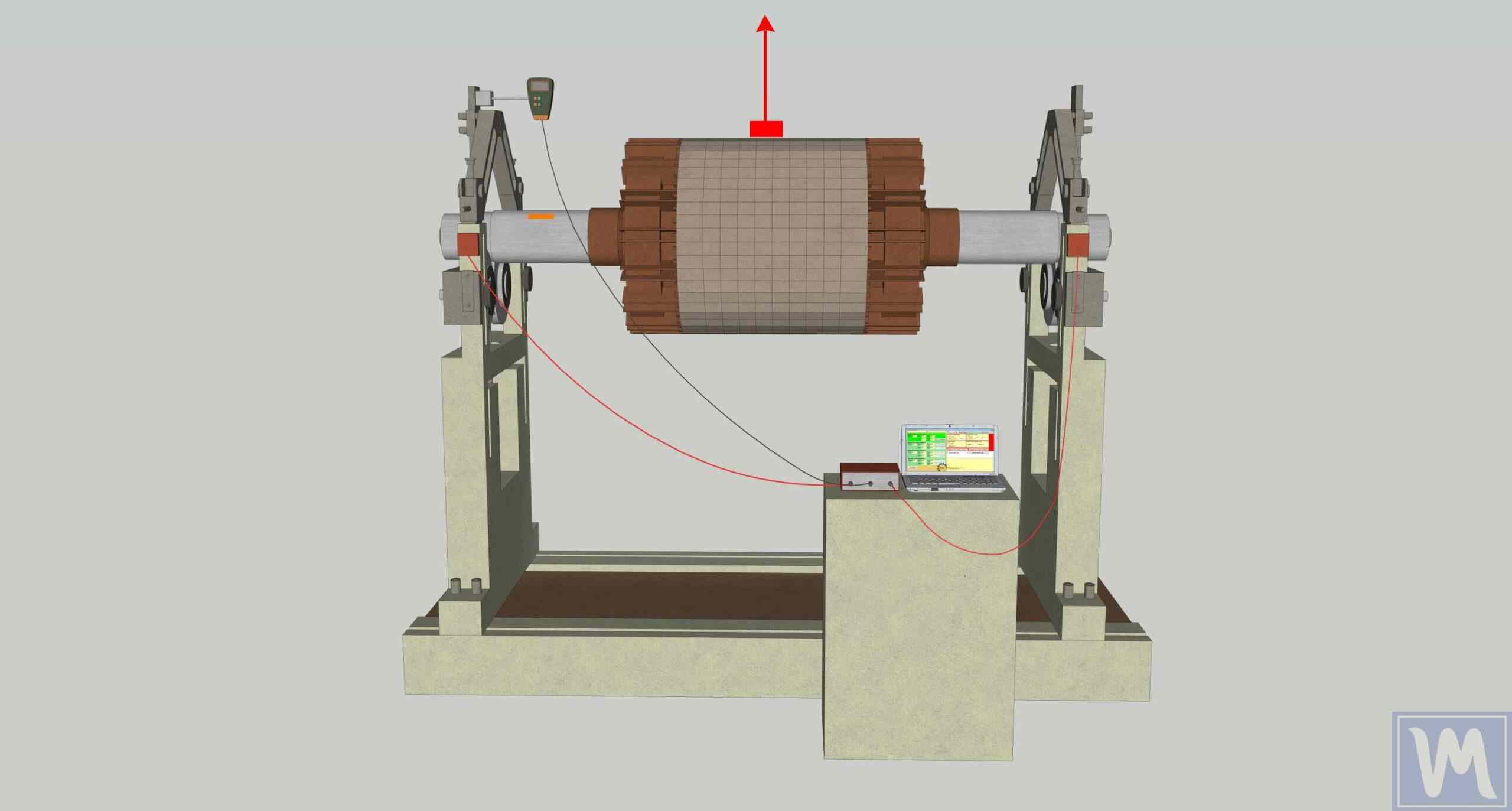

Watch YouTube Short Balanset-1A Rotor Balancing Tool: Ensuring Precision in Static Balancing Static balancing is a crucial process for the optimal performance of various mechanical systems. Among the tools designed for this purpose, the Balanset-1A stands out. This device is specifically engineered to address the question: What tools are used for the static balancing of impellers? In this article, we will explore the features, setup, and best practices for using the Balanset-1A for effective rotor balancing. Understanding the Importance of Rotor Balancing Before diving into the specifics of the Balanset-1A, it is essential to understand why rotor balancing is necessary. Imbalances in rotating machinery can lead to increased vibrations, which may result in premature wear, damage, or even catastrophic failures. Ensuring that a rotor is balanced not only enhances performance but also extends the lifespan of the machinery. Preparing for Balancing Before initiating the balancing process with the Balanset-1A, it is vital to ensure that the mechanisms involved are in good working condition. This includes: Ensuring the rotor is securely mounted in its designated position. Checking that the bearings are functional and properly installed. Cleaning the rotor to remove any contaminants that might interfere with the balancing process. Additionally, it is recommended to conduct preliminary measurements while in vibration meter mode. This helps in identifying the overall vibration levels and discerning whether the rotor imbalance is a significant contributor to the machinery's vibrations. Setting Up the Balanset-1A When preparing to use the Balanset-1A, the placement of vibration and phase sensors is critical. Follow the manufacturer's guidelines for sensor installation to ensure accurate readings. If the total vibration levels (V1s and V2s) are approximately equal to the rotational components (V1o and V2o), it can be inferred that rotor imbalance is likely the primary cause of excessive vibrations. Conversely, if the total vibration significantly exceeds the rotational component, a thorough inspection of the machine is warranted. This could involve checking the integrity of the bearings, the foundation mounting, and ensuring there are no obstructions during the rotor's operation. Pre-Balancing Checks Prior to using the Balanset-1A, it is prudent to verify the absence of any substantial static imbalance. For horizontally aligned rotors, you can manually rotate the rotor 90 degrees from its current position. If the rotor tends to settle in a position of equilibrium, it indicates static imbalance. To address this, place a balancing weight at the topmost point of the rotor, ideally in its midpoint. The weight should be calibrated so that the rotor remains stationary in any position, significantly reducing the vibration during the initial startups of a heavily unbalanced rotor. Conclusion The Balanset-1A is an invaluable tool for professionals seeking to maintain the integrity and performance of their mechanical systems through effective static balancing of impellers. By adhering to proper preparation and setup procedures, users can ensure that they achieve optimal results, minimizing wear and tear while enhancing overall system efficiency. In the realm of industrial machinery, understanding what tools are used for the static balancing of impellers is crucial, and the Balanset-1A certainly meets this need with precision and reliability. Contact Information: For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu. Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera. Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/. Buy Balanset-1A on Facebook Marketplace Balanset-1A OEM on Etsy

律师尚未回复,请耐心等待!

Watch YouTube Short

Watch YouTube Short

辽公网安备:

辽公网安备: